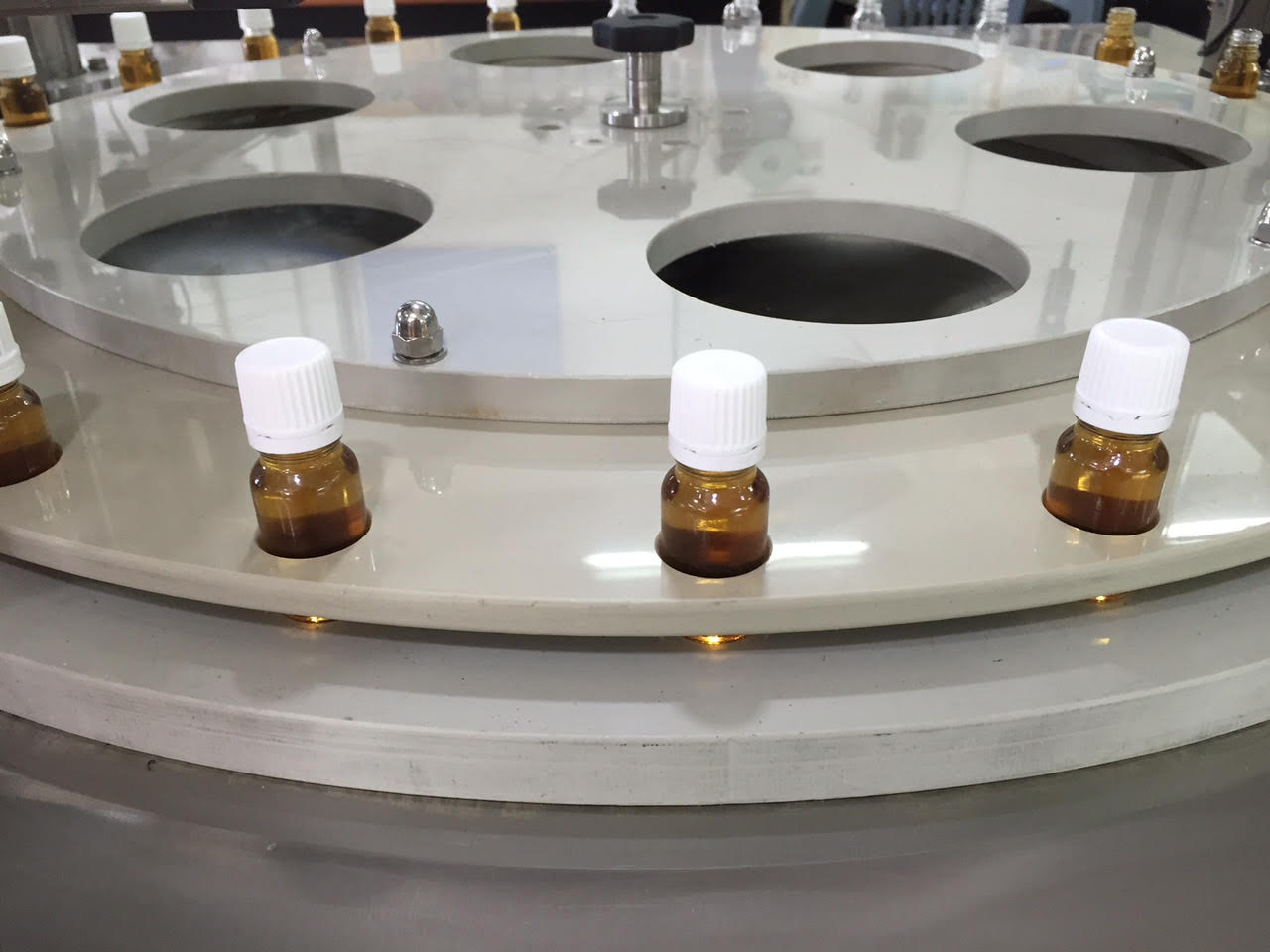

SPINNER-J MONOBLOCK

Multi-range filling, sealing & capping automatic machine

After years of manufacturing packaging machines for customers in the Cosmetics and Pharmaceutical fields, we have extensive knowledge of the needs and challenges faced by small to large manufacturers on daily basis.

This foundation has enabled us to develop a series of machines that provide an answer for long and short production batches.

Finally, we have now brought together all our proven technologies for the first time in a single Monoblock Fill, seal and Cap machine dedicated to both, pharma and cosmetics sector.

The SPINNER MONOBLOCK is a unique and truly packaging machine, which enables the possibility to combine filling, sealing and capping procedure all in one dedicated, and space saver machine.

After years of manufacturing packaging machines for customers in the Cosmetics and Pharmaceutical fields, we have extensive knowledge of the needs and challenges faced by small to large manufacturers on daily basis.

This led us to develop the SPINNER MONOBLOCK – “Fill-Seal-Cap” machine for Bottles, Jars, and Vial.

This series offers significant productivity enhancements that will benefit manufacturers and boost efficiency.

The SPINNER MONOBLOCK’s design answers all aspects of your core production needs, capping, over capping, sealing, labeling, and discharging.

With dedicated models for every possible combination, the SPINNER MONOBLOCK Series is your all-in-one pharmaceutical and cosmetics production solution.

The SPINNER MONOBLOCK model is designed to provide the ultimate solution for cosmetic and pharmaceutical manufacturers.

The machine can deal with a wide range of bottles and containers of different shapes and sizes in small/medium scale batches.

This is one of the company’s flagship rotative machines, and it is very popular among cosmetic manufacturers worldwide, due to its versatility in filling and capping a wide range of products.

The SPINNER MONOBLOCK boasts the latest technology in its field, with full servo operation in the filling and capping stations. Its ergonomic design is super efficient and user-friendly, offering the operator quick changesets, with no tools required. These benefits and many others guarantee that the SPINNER MONOBLOCK is your next partner for success.

Main features:

- Automatic container alimentation by rotative feeding table.

- Servo index operation.

- Filling system – Option 1: Servo operation piston filler station, designed to fill all range of watery and foamy to dense and viscous products. The Filling unit Trolley is on wheels – Integrated with the machine body, Extractable & Portable with SPECIAL QUICK FIT connection, for space-saving, unique visual result, and easy cleaning.

- Filling system – Option 2: E+H [Endress Hauser] DOSIMASS mass flowmeter for dosing control & Set of nozzles with a shutter to fill avoiding liquid tails and drops

- Upper 35 liter hopper designed with a quick connection to customers’ pump.

- Manual cap feeding.

- Servo operation capping station, designed to work with any types of caps such as:

standard screw caps, triggers, pumps, push-pull, press, etc. - Lower structure station designed to connect inkjet for bottom batch number printing.

- Auto container ejection for exit conveyor.

- Ergonomic design for maximum work comfort.

- Easy to disassemble for cleaning, no tools required.

- Safety doors structure.

- The machine is manufactured from stainless steel, anodized aluminum, and plastic, which conform to

CE, FDA, and 3A standards.

Additional Options:

- Extra piston filler station for filling multi-phase products.

- Index rotary forms for different container shapes.

- Additional capping adapter for different cap types.

- Automatic cap feeding station.

- Automatic product feeding station.

- Teleassistance through a modem via internet.

Gallery

Film

- Tahini jar double filling & capping

- Nuts jar filling & capping

- Tahini jar filling & capping

- Scrab filling oil & salt